Industry News

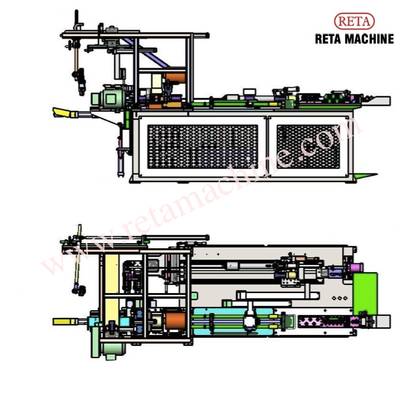

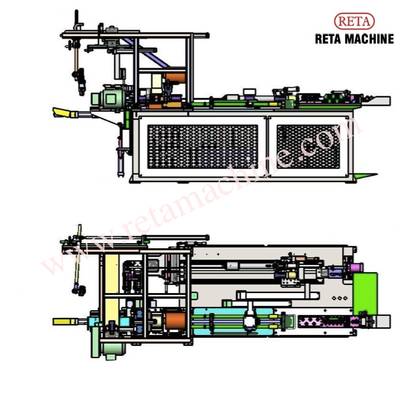

In the dynamic landscape of modern manufacturing, the advent of cutting-edge technologies has continually reshaped industry standards. Among these transformative innovations, Tube Integrated Machines stand out as a revolutionary force, redefining efficiency and precision in manufacturing processes.

Revolutionizing Production Workflows

Tube Integrated Machines have emerged as game-changers in the manufacturing sector, streamlining and enhancing production workflows. These machines seamlessly integrate various functions, from tube cutting to bending and end-forming, into a single, efficient process. This integration not only accelerates production but also minimizes manual handling, reducing the risk of errors and improving overall accuracy.

Precision at its Pinnacle

One of the standout features of Tube Integrated Machines is their unparalleled precision. These machines utilize advanced technologies such as CNC (Computer Numerical Control) systems to execute intricate tube fabrication tasks with microscopic accuracy. The result is a level of precision that ensures consistency in product quality, meeting the stringent demands of modern manufacturing standards.

Optimizing Material Usage

Efficiency is not just about speed; it's also about resource optimization. Tube Integrated Machines excel in maximizing material usage, minimizing waste through precise cutting and forming processes. This not only contributes to cost-effectiveness but also aligns with sustainable manufacturing practices, reducing the environmental impact of industrial processes.

Versatility in Applications

The versatility of Tube Integrated Machines adds another layer to their impact on manufacturing. These machines are capable of handling various tube materials, sizes, and shapes, offering manufacturers a broad spectrum of applications. Whether it's automotive components, furniture, or intricate architectural elements, Tube Integrated Machines adapt seamlessly to diverse manufacturing needs.

Seamless Automation for Increased Productivity

Automation is a cornerstone of efficiency in modern manufacturing, and Tube Integrated Machines embrace this principle wholeheartedly. These machines are designed for seamless automation, allowing for continuous operation and increased productivity. Automated processes not only speed up production but also reduce labor costs and the risk of human errors.

Challenges and Solutions in Implementation

While the benefits of Tube Integrated Machines are undeniable, their successful implementation comes with challenges. Manufacturers need to invest in training their workforce to operate and maintain these sophisticated machines. Additionally, the initial setup and integration into existing production lines require careful planning to ensure a smooth transition.

Conclusion: A Paradigm Shift in Manufacturing Dynamics

Tube Integrated Machines mark a paradigm shift in manufacturing dynamics, bringing forth a new era of efficiency, precision, and versatility. As industries embrace these advanced technologies, they open doors to increased productivity, reduced costs, and a sustainable approach to production. The impact of Tube Integrated Machines is not merely a trend but a transformative force shaping the future of manufacturing.

Revolutionizing Production Workflows

Tube Integrated Machines have emerged as game-changers in the manufacturing sector, streamlining and enhancing production workflows. These machines seamlessly integrate various functions, from tube cutting to bending and end-forming, into a single, efficient process. This integration not only accelerates production but also minimizes manual handling, reducing the risk of errors and improving overall accuracy.

Precision at its Pinnacle

One of the standout features of Tube Integrated Machines is their unparalleled precision. These machines utilize advanced technologies such as CNC (Computer Numerical Control) systems to execute intricate tube fabrication tasks with microscopic accuracy. The result is a level of precision that ensures consistency in product quality, meeting the stringent demands of modern manufacturing standards.

Optimizing Material Usage

Efficiency is not just about speed; it's also about resource optimization. Tube Integrated Machines excel in maximizing material usage, minimizing waste through precise cutting and forming processes. This not only contributes to cost-effectiveness but also aligns with sustainable manufacturing practices, reducing the environmental impact of industrial processes.

Versatility in Applications

The versatility of Tube Integrated Machines adds another layer to their impact on manufacturing. These machines are capable of handling various tube materials, sizes, and shapes, offering manufacturers a broad spectrum of applications. Whether it's automotive components, furniture, or intricate architectural elements, Tube Integrated Machines adapt seamlessly to diverse manufacturing needs.

Seamless Automation for Increased Productivity

Automation is a cornerstone of efficiency in modern manufacturing, and Tube Integrated Machines embrace this principle wholeheartedly. These machines are designed for seamless automation, allowing for continuous operation and increased productivity. Automated processes not only speed up production but also reduce labor costs and the risk of human errors.

Challenges and Solutions in Implementation

While the benefits of Tube Integrated Machines are undeniable, their successful implementation comes with challenges. Manufacturers need to invest in training their workforce to operate and maintain these sophisticated machines. Additionally, the initial setup and integration into existing production lines require careful planning to ensure a smooth transition.

Conclusion: A Paradigm Shift in Manufacturing Dynamics

Tube Integrated Machines mark a paradigm shift in manufacturing dynamics, bringing forth a new era of efficiency, precision, and versatility. As industries embrace these advanced technologies, they open doors to increased productivity, reduced costs, and a sustainable approach to production. The impact of Tube Integrated Machines is not merely a trend but a transformative force shaping the future of manufacturing.